The Challenge

Composite finishing is one of the most labor-intensive steps in carbon fibre production. Achieving a flawless surface requires skill, time, and consistency — but traditional manual sanding and polishing presented major issues:

- Delamination & Surface Damage – Inconsistent sanding pressure weakens material integrity.

- Inconsistent Quality – Results vary between operators, causing defects and rework.

- Health & Safety Risks – Fine dust and chemical exposure threaten long-term worker health.

- Slow & Expensive – Skilled labour is scarce, and manual finishing is time-consuming.

- Difficult to Automate – Traditional robot programming is too complex and inflexible.

The Solution: Mimic by Nordbo Robotics

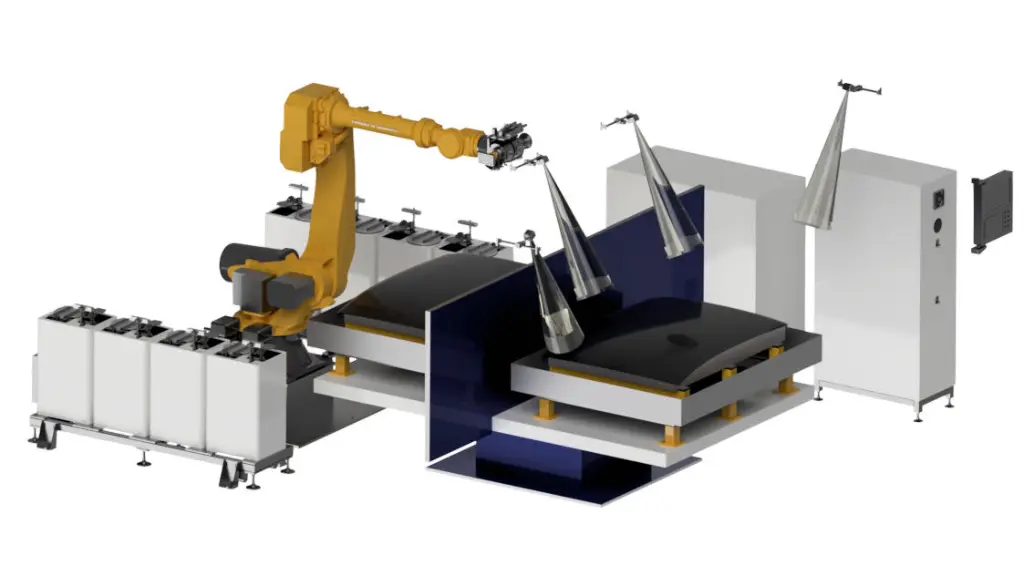

To automate finishing of large carbon fibre parts, Nordbo Robotics delivered a complete Mimic-based robotic system tailored to the customer’s needs:

-

Part Handling

- Large turntable for automated part infeed.

- Fixtures weighing several hundred kilograms, loaded with forklifts.

- Each fixture equipped with a digital ID, allowing automatic recognition of products and seamless program selection.

-

Programming & Teaching

- 4 OptiTrack cameras provided high-precision tracking of operator demonstrations.

- Operators could choose between multiple teaching joysticks to program sanding, polishing, and dispensing tasks.

- Programs could also be created on parts outside the cell, enabling offline preparation.

-

Tooling & Automation

-

A multi-tool end-effector equipped with:

- Square sander

- Circular orbital sander

- Spray dispensing tool for abrasive liquid and water cleaning

- Automatic abrasive change system with 8 change stations.

- Eliminated need for manual tool changes.

-

A multi-tool end-effector equipped with:

-

Process Performance

- Part cycle times: 20–40 minutes, depending on part complexity.

- Delivered with 8 validated part programs at installation.

The Results

With the Mimic-based solution, the customer achieved:

- 100% consistency in surface quality

- 50% reduction in rework and scrap

- Safer, healthier work conditions

- Rapid return on investment

The Nordbo Process

To ensure success, Nordbo Robotics followed its structured Complete System Design process:

- Define Scope – Understand customer’s quality goals & workflow needs.

- Design Solution – Simulate and validate finishing strategies with Mimic.

- Deploy & Train – Install system and train operators for self-sufficiency.

- Support & Scale – Ongoing updates and options for multi-line rollout.

Conclusion

By combining Mimic no-code programming with advanced part handling and multi-tool automation, the world’s largest carbon fibre producer transformed sanding and polishing from a labour-intensive bottleneck into a safe, scalable, and repeatable process.