Intelligent Visual Inspection with Phoenix & Hawk

Rethinking Quality Inspection - Manufacturers face two big challenges in quality control:

- Manual inspection is inconsistent, costly, and hard to scale.

- Traditional vision systems are fragile, requiring endless tweaking and still missing subtle defects.

The result? Missed errors, high rework costs, and frustrated teams.

Meet the Platform

Phoenix – Smarter Model Training

- Simple annotation tools, accessible from any PC

- Fast, secure training in the cloud or on-premise

- Continuous model improvement with new data

- Clear performance feedback to track progress

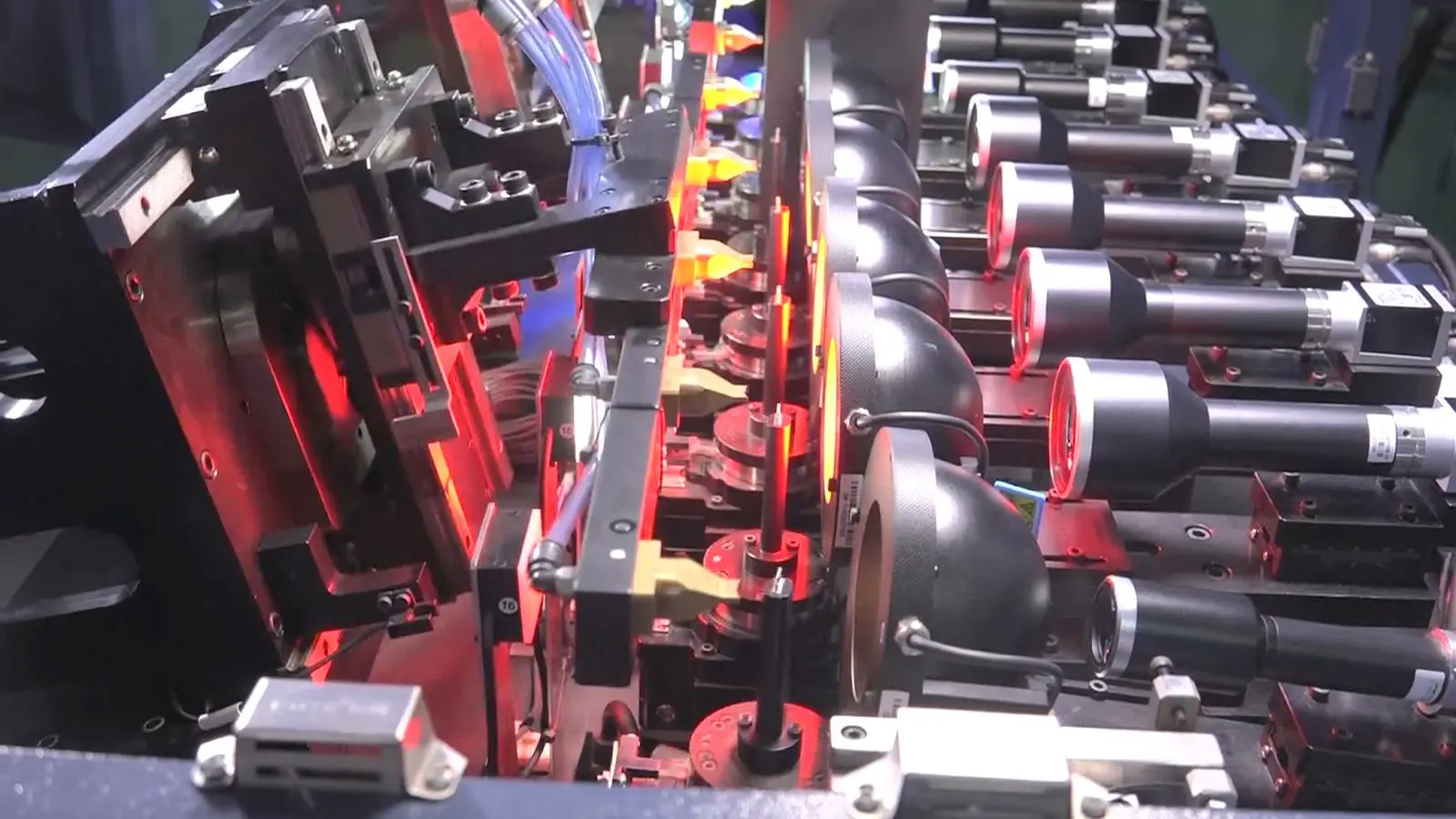

Hawk – Real-Time Quality Assurance

- Runs next to your production line

- Connects directly to cameras and PLCs

- Detects multiple defect types in milliseconds

- Delivers actionable insights with live visualization and statistics

How It Works

1

Collect & Label

Use Phoenix to quickly annotate your product images.

2

Train & Optimize

Generate AI models and fine-tune them with feedback.

3

Deploy & Inspect

Run those models in Hawk for real-time defect detection.

4

Improve Continuously

Feed inspection data back into Phoenix to keep getting better.

Reduce rework and scrap costs

Free up skilled workers for higher-value tasks

Ensure consistent quality across all sites

Scale inspection without scaling headcount

Ready to embark on a journey of digital transformation?

Let's turn your vision into reality. Contact us today to set your brand on the path to digital excellence with us.