Catch Every Defect — Automatically

Complete AOI solutions that detect defects automatically, reduce rework, and ensure consistent quality — tailored to your parts and production line.

Automated Inspection Tailored to Your Needs

We specialize in delivering automated inspection systems for small parts under 200mm — from proven standard machines to fully customized solutions. And when your needs go beyond machines, our software stack powers advanced vision projects across industries.

Standard Machines

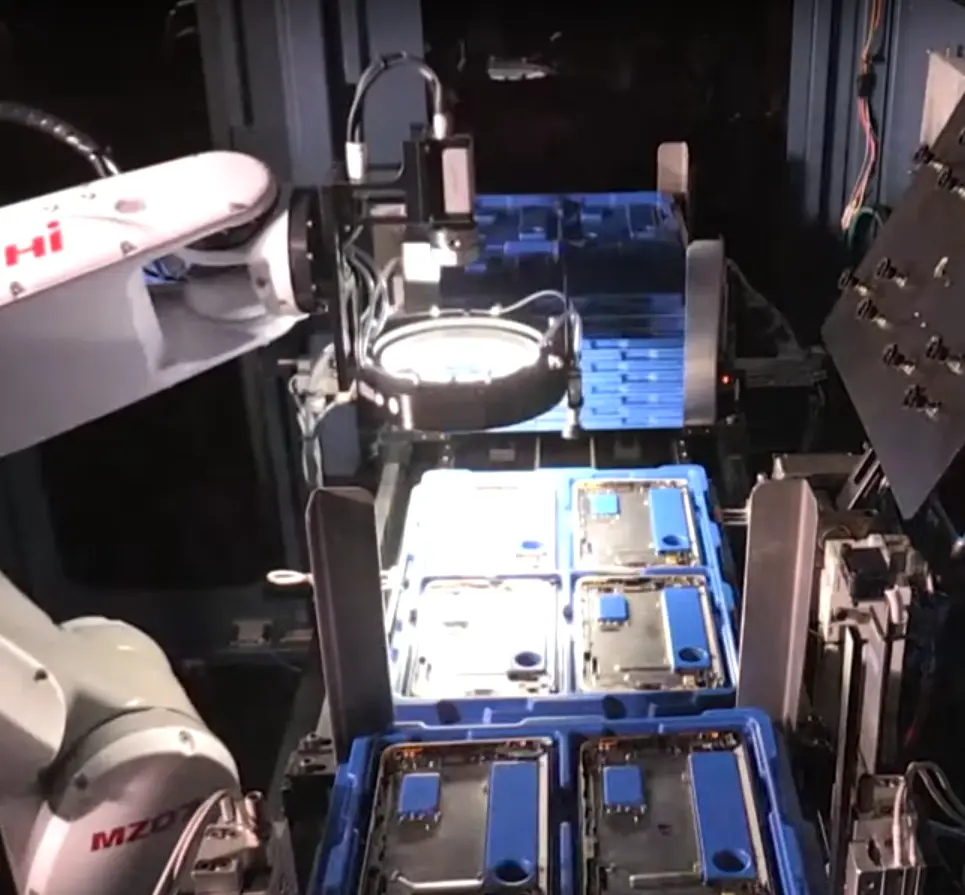

Pre-engineered inspection cells designed for small parts (<200mm). Fast delivery, proven reliability, and optimized for common inspection tasks like cosmetic defect detection, micro-weld analysis, and surface finishing control.

Customized Machines

Tailored inspection systems built for your specific parts(<200mm) and processes. We adapt cameras, lighting, and fixtures to ensure reliable defect detection in your unique production environment.

Surface Inspection Projects

Beyond machines, our software stack (Phoenix + Hawk) can power advanced inspection projects. From multi-camera setups to large-scale production monitoring, we work with you and your integrators to deliver scalable vision solutions.

Reach out tell us about your project

Platforms Behind Our Solutions

Phoenix – Cloud AI Platform for Inspection Projects

Phoenix is the platform where your AOI solutions are created and managed. It allows you to:

- Create multiple projects and collaborate with multiple users.

- Upload images from any number of cameras.

- Annotate defects with masks, supported by AI-assisted labeling.

- Use AI-based cropping or define simple cropping rules for controlled setups.

- Train and evaluate models with pretrained networks for specific tasks.

- Outsource labeling with our annotation service if needed.

- Work in a clean, intuitive interface designed for speed and accuracy.

👉 Phoenix helps you move from raw images to production-ready inspection models — quickly and efficiently.

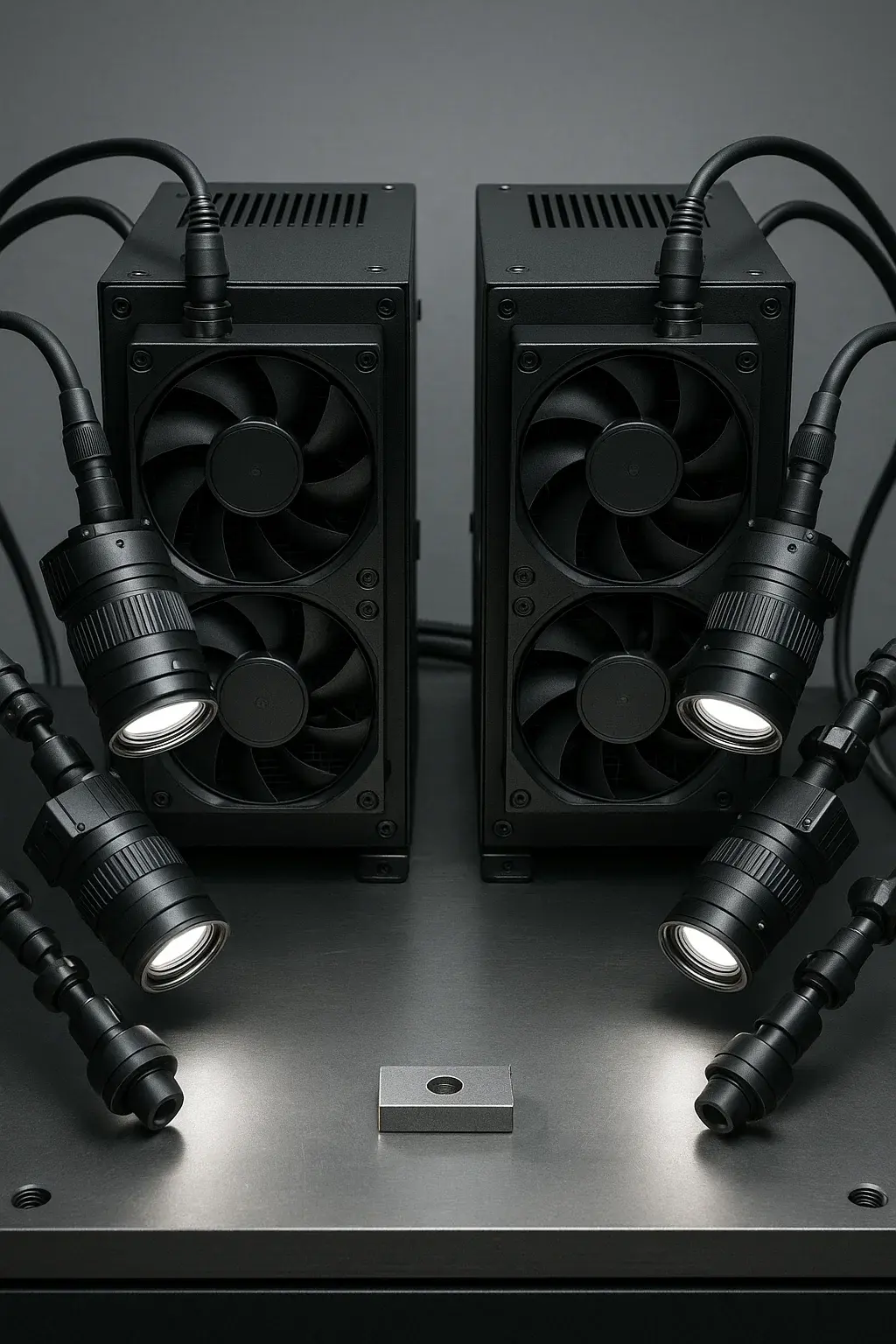

Hawk – Runtime Inspection Engine

Hawk is the deployment layer, running AI and vision pipelines inline on your production floor.

- Scales from simple single-camera setups to multi-device, 30+ camera systems

- Supports USB3 and GigE camera sources

- Leverages NVIDIA CUDA GPUs (single or multiple per device)

- Runs Phoenix-trained AI models plus custom C++ or Python plugins for classic vision tasks

- Connects with PLCs for hardware triggering, synchronization, and result output

- Designed for both standalone edge devices and complex multi-camera inspection cells

👉 Hawk ensures your inspection models run in real-time production with the speed, flexibility, and robustness your line requires.

AI-powered Quality Inspection

Automate defect detection with vision-based AI. Our QC platform improves consistency, reduces waste, and cuts costs by spotting surface defects that humans often miss. Proven across electronics, pharma, and automotive, it adapts to your parts, scales with your production, and keeps getting smarter as more data is added.

Our latest content

Check out what's new in our company !