No-Code Programming Tools

Programming robots shouldn’t require coding expertise. At Nordbo Robotics, we develop no-code tools that let operators transfer their knowledge directly to robots.

Our two proprietary platforms, Mimic and CraftMate, enable intuitive programming that reduces setup time, empowers shop-floor staff, and scales automation across industries.

Why No-Code Matters

Empower workers

No need for coding, operators teach the robot directly.

Accelerate deployment

Reduce programming time from weeks to hours.

Increase flexibility

Adapt to new parts or products without costly reprogramming.

Capture expertise

Standardize and replicate best practices across multiple sites.

Smart Compensation with Sensors

No-code programming makes it easy to generate robot paths and processes. But in real production, parts aren’t always perfect. Tolerances, misalignments, and material variation need intelligent handling.

That’s why we combine our platforms with sensor-based techniques:

- Force sensors – detect contact and adjust paths dynamically.

- Vision sensors – locate parts and adapt to variation in position.

- Compensation units – mechanically adjust the tool to follow part tolerances.

These techniques enhance no-code programming by making robots adaptive to real-world conditions

Our Platforms

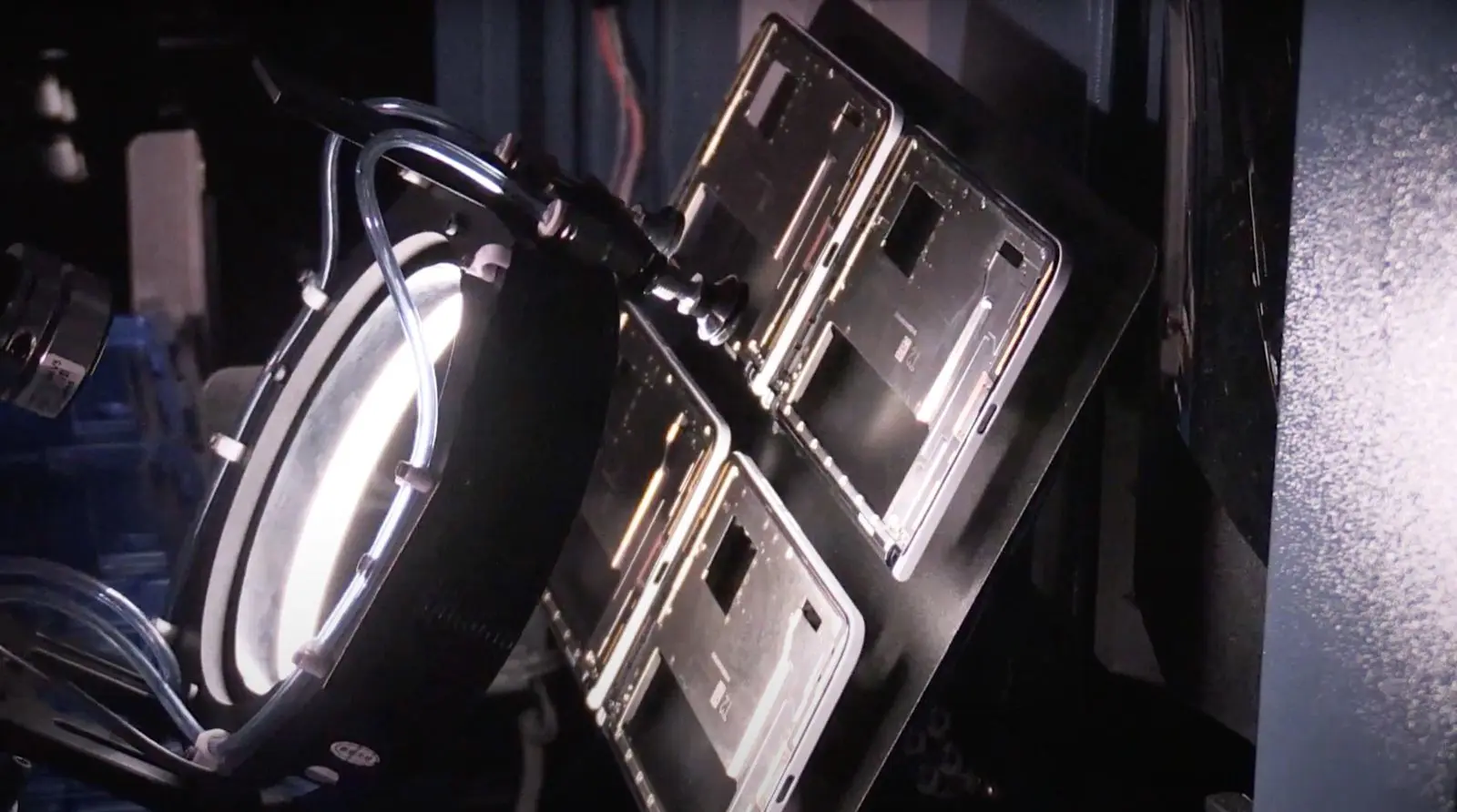

Mimic – Teach robots by demonstration

Operators simply demonstrate a task, and Mimic captures the motion in real time.

- Real-time “show and do” programming

- Ideal for painting, powder coating, sanding, grinding, polishing, dispensing

- Minimal training required

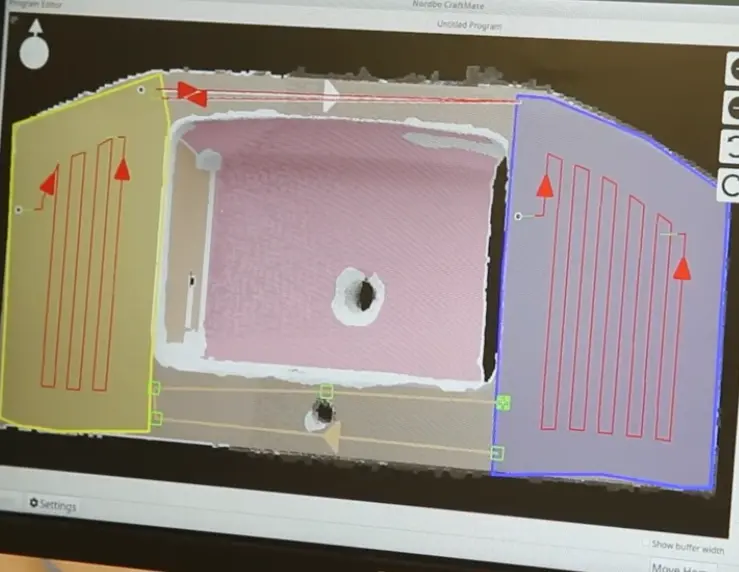

CraftMate – Scan and plan for adaptive automation

CraftMate allows the robot to scan a workpiece and apply predefined process rules. The operator specifies the rules once, and CraftMate adapts them automatically to each new part.

- 3D scanning of workpieces

- Apply user-defined or rule-based process areas

- Consistent surface treatment across part variations

- Perfect for sanding, painting, polishing, deburring

Phoenix – No-code AI for visual inspection

Phoenix enables manufacturers to create inspection models by simply showing the AI where defects appear in sample images.

- No coding required – just annotate defects

- Trains AI models tailored to your production

- Detects scratches, dents, miscoloring, and more

- Deploy models directly to Nordbo Edge Devices for real-time inspection

Business Value of No-Code

List and describe the key features of your solution or service.

Faster ROI

Deploy automation in weeks

Lower training cost

Upskill operators directly

Flexibility

Handle new parts without external programming

Scalable knowledge

Capture once, replicate everywhere