Automating Powder Coating with Human Skill at the Core

Powder coating often involves repetitive touch-ups on moving conveyors — a task that is dirty, demanding, and difficult to automate. With Mimic, operators can transfer their expertise directly to the robot in under 30 seconds, without stopping the line. The result: safer work conditions, consistent quality, and higher throughput.

From Dirty and Dangerous to Automated and Accurate

Manual powder coating touch-ups are tough to staff, hard to standardize, and expose workers to unhealthy environments. Automation with Mimic keeps the skill, but removes the strain.

Reduce Worker Exposure

Move people away from hazardous environments while keeping their expertise in play.

Consistent Quality

Robots repeat expert movements with precision, ensuring every part meets finish standards.

Fast ROI

Minimize downtime with quick programming — no long setup or robot expertise required.

Solve Labor Shortages

Reduce reliance on manual touch-ups while still leveraging skilled operators.

Unlock Consistency in Powder Coating Touch-Ups

Retrofitting your existing powder coating line with Mimic means better quality, less rework, and fewer bottlenecks – without replacing your Gema, Wagner, or other equipment.

The Challenge

Even with advanced powder coating systems, manual touch-ups remain a weak spot. They add variability, depend on skilled operators, and slow down production.

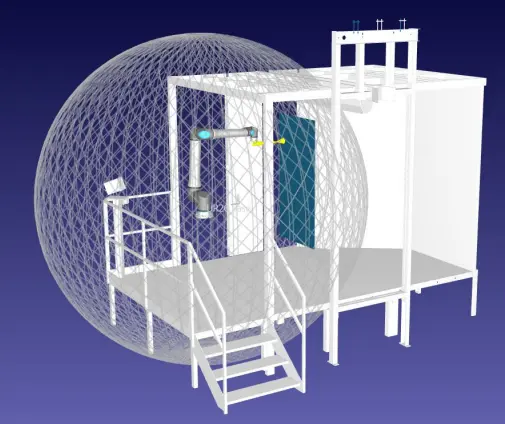

The Solution – Mimic Retrofit

With Nordbo Robotics’ Mimic platform, you can automate touch-ups by simply teaching the robot by hand. Operators demonstrate once, and the robot repeats perfectly – every time.

- Retrofit on existing Gema, Wagner, or similar setups

- Fast deployment – no complex programming

- Consistent quality in touch-up zones

- Lower rework rates and higher throughput

Why Retrofit Instead of Replace?

- Save costs by keeping your existing system intact

- Add automation where it matters most – the manual step

- Scale touch-up automation across multiple lines

From Manual to Automated: Brandt’s Retrofit Success

Discover how Brandt integrated Mimic into their existing powder coating setup. Hear directly from their team about the improvements in quality, reduced rework, and the simplicity of teaching robots with Mimic.

Skill Transfer Made Simple

A features section highlights your product’s key attributes, engaging visitors and boosting conversions.

Teach by Demonstrating

Operators create robot programs in 30 seconds, even while the conveyor runs.

Flexible Tracking

Choose between Vive (within ~10 mm) or OptiTrack (<1 mm) tracking depending on precision needs.

No-Code Programming

Eliminate complexity — Mimic requires no coding or robotics background.

Adaptable Integration

Works in retrofit paint booths or new lines, tailored to your exact workflow.

As Easy as Create or Run

Mimic’s operator interface keeps things simple for operators — create a new program in seconds, or run the right one automatically.

- Create Program - Record motions and coating inputs in real time — including on/off spray signals — so programs capture the full expertise of the operator.

- Run Program - Production systems can send product IDs directly to Mimic, ensuring the right program is auto-selected for each part on the line.

For Integrators

While Mimic is designed to be simple for operators, we know integration can be complex. That’s where we come in — our experts help connect Mimic to your conveyors, scanners, and PLCs, ensuring everything runs seamlessly. Reach out to us, and we’ll guide you through the setup.

How It Works – Powder Coating Touch-Ups with Mimic

1

Pause & Step In

Operator pauses the robot, slides it aside, and steps into the booth.

2

Teach by Doing

Wait for the conveyor signal. Start teaching by moving the robot and performing the touch-up exactly as you would manually, including powder on/off.

3

Save & Resume

Stop teaching, move the robot back, and unpause.

4

Automated Repeat

When the next part arrives, Mimic repeats the taught motions and powder sequence automatically. The cycle continues, waiting for each trigger.

Powder coating & painting cases

Check out what's new in our company !